Polaris G-code uses EIA-RS274D as a basis.

#Image to g code serial#

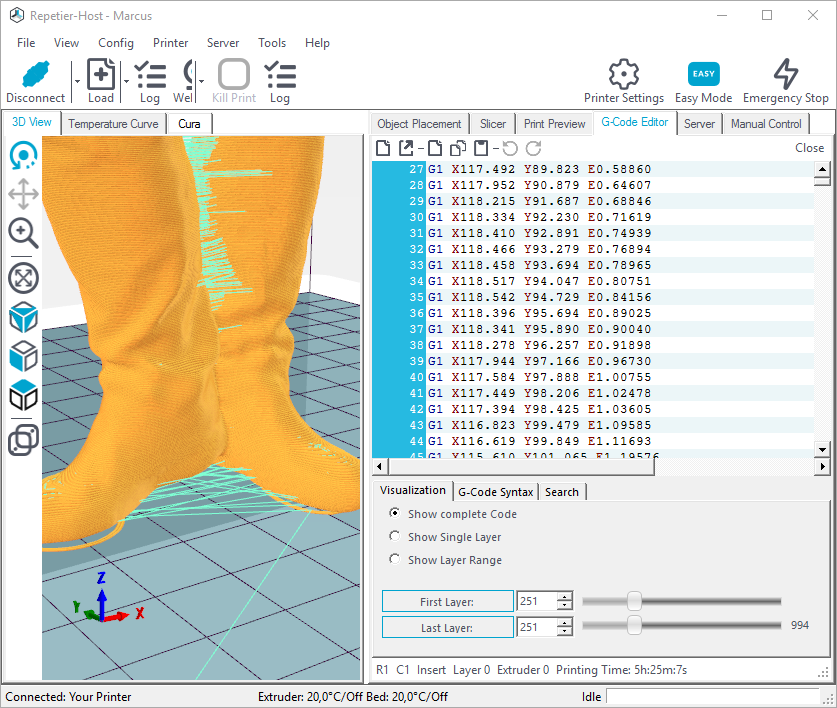

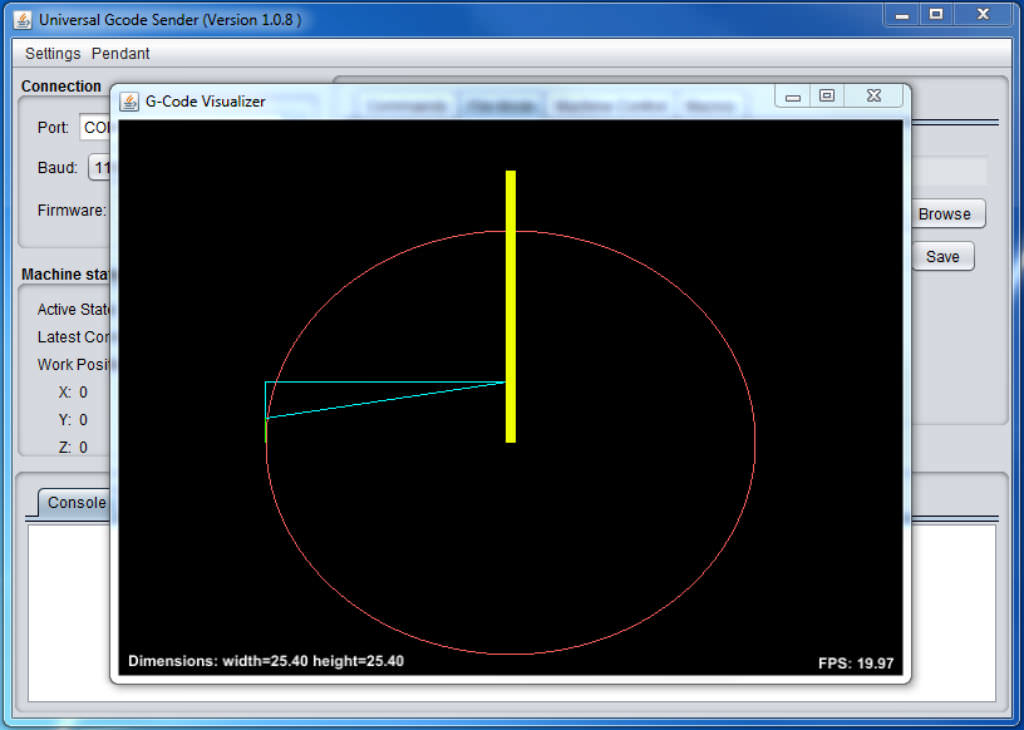

#Image to g code software#

The G-code software commands are specified with commands XYZ-PxPyPz, where XYZ are the 3D position of the tool tip and PxPyPz are the roll, pitch and yaw angles of the tool tip. G-code is specified in a Cartesian reference in the part coordinate system. Usually XYZ represent the linear stage, the ABC axes represent the rotational gimbal and UVW represent fast, short stroke motors such as laser Galvo scanner motors.Ĭartesian G-code™ is Polaris Motion’s new and novel G-code programming mode and it is now available when ordering a Polaris UniverseOne™ motion control system. The XYZ commands move the three linear stage axes, the ABC commands move the three rotational axes, and the UVW commands move actuators that are parallel to the XY and Z axes. Standard 9-Axis G-code is offered for controlling the XYZ-ABC-UVW motors of a machine tool. Polaris G-code has a wide breadth, it is complete in its offering, and it has been tested over decades. Many machine types are supported, including: mills, lathes, routers and waterjets, single-point diamond turning machines, precision laser machines, and robotic dispensing and welding machines. Polaris has been developing and refining its G-code language and computational engine since 1996. A powerful extension to G-code software is the Paramacro language, which adds variable names, program flow control and a comprehensive list of math functions. It provides instructions to a motion controller by way of a programming file to move the toolpath of a CNC machine tool in three dimensions using lines, arcs and splines. G-code is the most widely used programing language in the world for programming CNC machine tools. Infinite Field of View for 3-Axis and 5-Axis Machines.

This course is going to be a lot fun, so let's get started. We'll wrap it up with CNC machining a complete part, starting with spot drilling, drilling, tapping, and then using advanced adaptive contouring routines for the outside roughing and pocketing. The great thing about learning each of these codes is we can run them on a real CNC machine and then modify the codes to see what happens. We'll cover the basic codes, like rapid and feed moves, and then progress into more advanced topics, like cutter compensation and tapping. We're going to see firsthand how each of the G-codes operates and what's required to run on one of these machines. Then we're going to go over and head to the Haas Factory and run our programs on this machine. The first part of most movies will be learning about the codes and how they were created. We'll be focusing on the key G-codes and how they work and what they can make a CNC machine do.

#Image to g code how to#

In this course, we'll learn how to read, write, and understand G-code. Hi, I'm Gabriel Corbett, and welcome to G-Code Programming for CNC Foundations. Gabriel's interests include new ventures, photography, adventure travel, surfing, mountain biking, and stand-up paddleboarding. He has presented at SOLIDWORKS World in Dallas, San Diego, Florida, and Los Angeles. Additionally, he runs his own design engineering company called Tiger Industrial Inc. He runs the Orange County SOLIDWORKS User Group, and has taught SOLIDWORKS and CNC machining at Irvine Valley College. Gabriel has been a author since 2011, and has developed courses on SOLIDWORKS, Onshape, rapid prototyping, and certification. He has worked on all aspects of product development, including product design, engineering, marketing, sales, and management.

Gabriel has worked with many startups and established companies, developing products for the consumer, industrial, and medical markets. He regularly consults companies on better and more efficient manufacturing and design methods. By combining solid design experience with real-world skill in building products, Gabriel has the unique ability to design products quickly and effectively. He previously owned a prototype-through-production machine shop that built parts for notable organizations like the Jet Propulsion Laboratory (JPL) and Panasonic. Gabriel has a bachelor of science degree in mechanical engineering, and has been an active product designer for the past 18 years. Gabriel Corbett is an experienced product designer, instructor, and speaker.

0 kommentar(er)

0 kommentar(er)